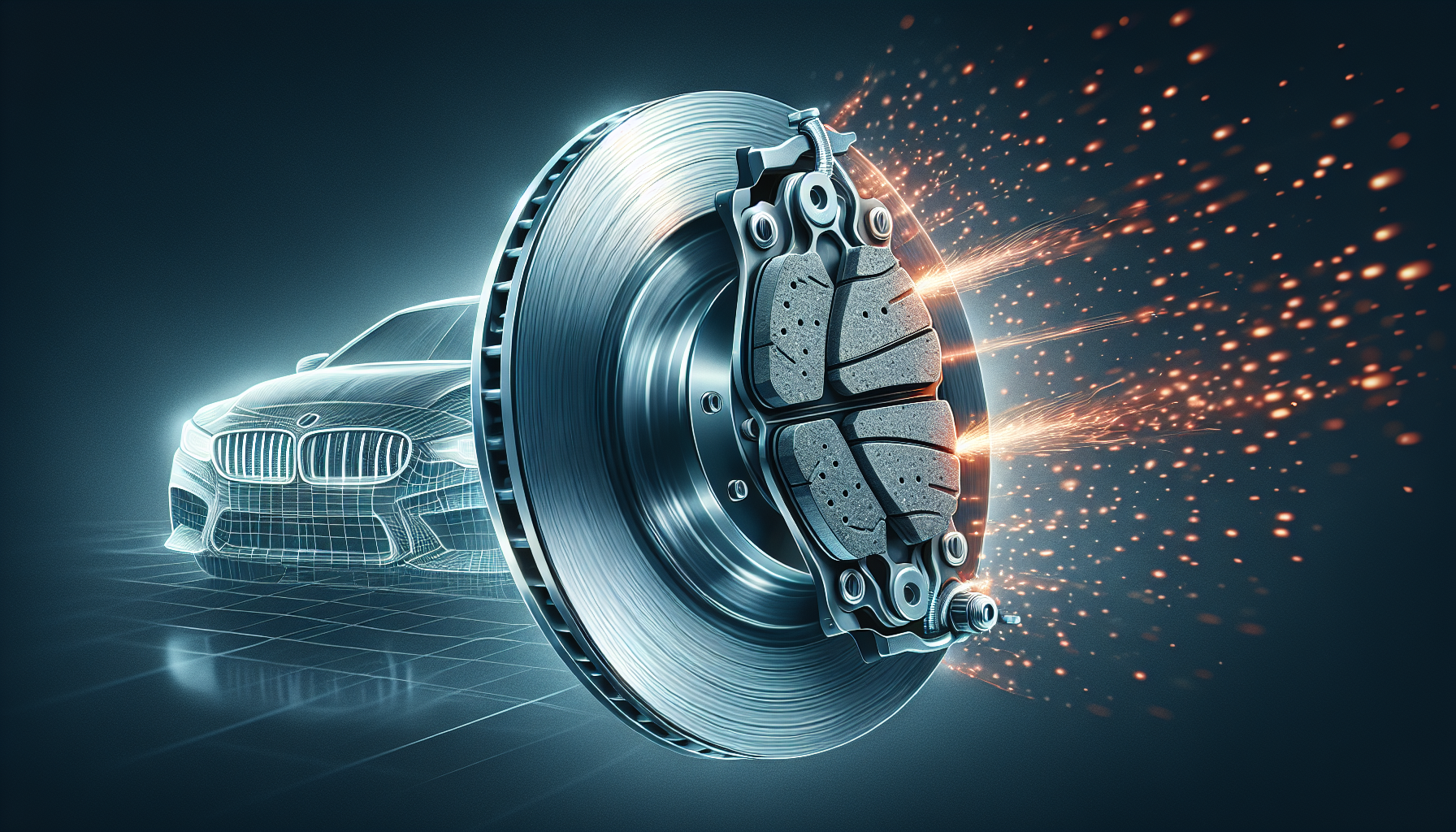

Why breaking in brakes is important? Simply put, it is crucial for ensuring the safety, performance, and longevity of your vehicle’s braking system. Properly bedding new brakes creates a smooth and even layer of friction material on the rotors, which translates to more consistent stopping power and prevents issues like brake noise and vibration. Fail to do this, and you may compromise not just the effectiveness of your brakes, but also their lifespan. This article delves into the how and why of the break-in process, so you can drive with confidence and control.

Key Takeaways

- Bedding in new brakes is crucial as it creates a uniform layer of friction material on the rotors, enhances braking performance, and prevents issues like vibrating pedals and steering wheel shudders. The brake bedding process ensures these benefits are achieved effectively.

- Skipping the bed-in process for brakes can result in uneven deposits on rotors, compromised stopping power, a rough driving experience, and increased wear and tear on brake components.

- A proper bedding process for brakes involves controlled heating and cooling cycles to ensure optimal friction, reduce noise, extend the lifespan of braking components, and cater to specific types of brake systems, including high-performance and everyday vehicles.

Is breaking in brakes really necessary?

Have you wondered why seasoned mechanics emphasize the importance of properly breaking in new brake pads? This critical process isn’t just a customary step. It’s essential for ensuring your vehicle’s safety and achieving peak performance from your braking system. The brake bedding procedure involves embedding an even layer of pad material onto the rotor surfaces through controlled use of the brakes, thus enhancing friction and overall braking efficiency. Ignoring this crucial process could lead to reduced effectiveness and a lackluster response when you assess how well your fresh brakes perform.

Overlooking the break-in sequence can result in undesirable issues such as vibrating pedals, shaking throughout the vehicle, or tremors felt in the steering wheel—troubles that are best avoided. By executing this initial embedded interaction between pads and rotors via regulated heating up followed by cooling down cycles help prepare brakes to function at optimal levels consistently while also preventing brake fade thanks to expulsion of gases trapped within the pad material during manufacturing.

What happens if I don’t break in my brakes?

Neglecting the proper brake bedding process for new brake pads is like failing to wear a pair of new shoes – it can cause discomfort and may lead to harm. With regards to your braking system, this neglect could result in:

- Unequal distribution of pad material on the rotor surfaces

- An inconsistent ride quality

- Reduced efficiency when slowing down

- The inability for the brakes to deliver optimal performance as fresh brake pads interact with untouched rotors.

Without suitable bedding between rotors and pads at elevated temperatures, both abrasive and adherent friction dynamics might degrade. This can produce unreliable braking performance that may undermine confidence in your vehicle’s safety during operation.

The Essence of the Bed-In Process for Brake Pads and Rotors

Ensuring the utmost performance of your braking system hinges on the successful completion of the brake bedding procedure. Known as ‘bedding,’ this method involves a deliberate sequence of heating and cooling to facilitate an even transfer of pad material onto the rotors. This crucial conditioning step enhances brake efficacy, response, and maximizes stopping force—a critical factor when fitting new brake pads.

When carried out correctly, this procedure yields enhanced smoothness during braking events and optimal operational capacity characterized by a consistent layering of pad material across the rotor’s surface.

The Role of Heat and Pressure

The brake bedding process involves a carefully controlled heating and cooling cycle that results in the brake pads wearing down slightly to fit the surface of the rotor perfectly, achieving synchronized operation between these critical components. This phase leads to a transfer of an even, fine layer from the pad onto the rotor through progressively higher heat levels. The advantages include:

- Elevated friction levels between pad and rotor

- A marked decrease in braking noise

- Enhanced performance and safety for your vehicle’s braking system.

Such an evenly distributed layer of pad material on the rotor is indicative of successfully bedding in your brakes and it significantly improves braking effectiveness.

Creating the Perfect Match

Just as a lock is designed to fit its key, the brake bedding procedure ensures that brake pads and rotors conform to one another for flawless functioning. The bedding process meticulously shapes this relationship, facilitating consistent wear and reliable braking capacity. Properly bedded brakes not only interact harmoniously, but also exhibit more uniform degradation, greatly benefiting the longevity of your brake system parts.

An evenly distributed layer of pad material on the rotor—achieved through successful bedding—is critical in preventing unwelcome noise and vibration during braking. This holds true for both pads and shoes. Each requires a proper break-in period to achieve peak performance levels within the braking system.

The Consequences of Skipping the Break-In Procedure

Imagine yourself hitting the race track with your vehicle outfitted with fresh brake pads, only to encounter persistent vibrations and a pedal that reverberates like a jackhammer underfoot. Overlooking the crucial brake bedding process can lead to several issues.

- haphazard pad material deposits on rotors

- pulsating pedals

- shakes in the steering wheel

- plummeting effectiveness of braking

Employing aggressive braking tactics without allowing new brakes proper bed-in time may cause them to fade or emit smoke – indicative of unevenly applied pad material which could inflict damage on your precious brake partners. In extreme scenarios, this oversight might even alter the crystal structure of rotor metal due to excessive heat spots, rendering it fragile and dangerously compromised.

Neglecting the essential step of bedding in new pads often results in telltale warped rotors and glazed pads—evidence that stresses why adhering strictly to recommended procedures is imperative for longevity and maintaining optimal performance within your car’s braking system. Consequently, when fitting new brakes onto your automobile, ensure consideration is given not just for replacing old pads, but potentially also installing brand-new rotors so that together they afford an effective enhancement overall.

Pulsing Pedals and Steering Wheel Shake-Up

If you notice a distinctive pulsing feeling through the brake pedal, steering wheel, or the whole car when braking, this could be an indication that your brakes have not undergone a proper brake bedding process. The uneven application of material onto the rotors can cause these vibrations during braking and lead to sensations like a shaky steering wheel or vibrating brake pedal.

Such signals — a pulsating sensation at the brake pedal and tremors felt on the steering wheel— while bothersome, are also alerting you to potential safety risks with your vehicle’s braking system.

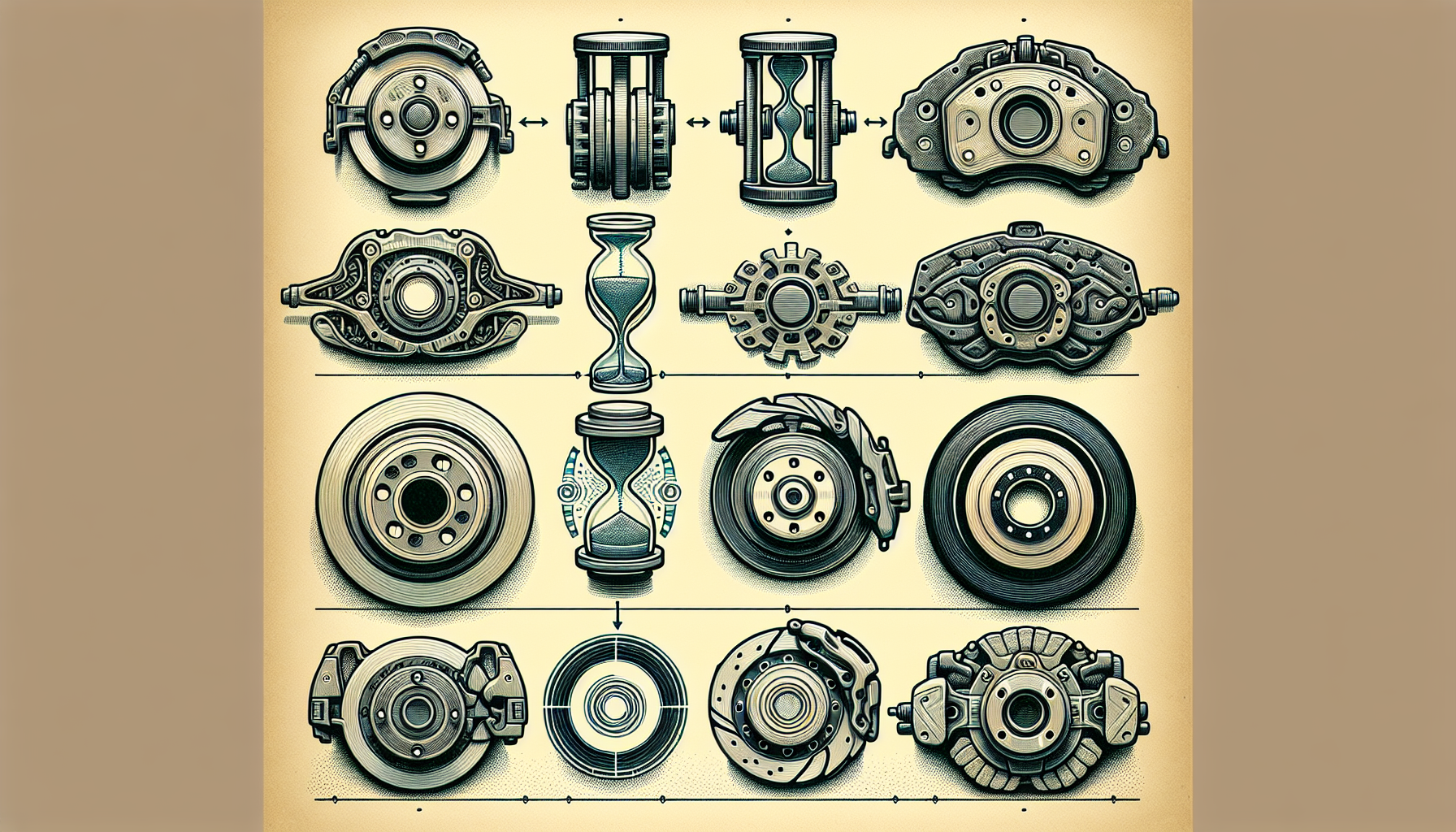

The Longevity of Your Braking System

Ensuring the longevity of your braking system hinges on how well you handle the brake bedding procedure. This process, much like a meticulous tune-up for your brakes, purges impurities and minimizes glossing over of both pads and rotors—enhancing uniformity in wear while prolonging their operational life. Neglect to adequately bed brake pads and rotors can result in suboptimal functionality and hastened deterioration, comparable to undertaking an extensive run with unseasoned footwear. Such oversight can undermine the abrasive and adhesive friction essential for a potent braking system leading to early degradation—a scenario preventable through correct bedding techniques.

Not All Brakes Are Created Equal: Bedding Variations

Just as athletes tailor their training to fit the particular demands of their sport, so too must different brake systems undergo distinct brake bedding processes to ensure they function at their best. Here is how various braking setups may require unique approaches during this crucial process.

- Ceramic pads often need a series of moderate to aggressive stops. This action helps deposit an even layer of friction material onto the rotors, ensuring that the brakes perform optimally and last longer.

- Carbon-fiber braking systems might call for a specialized heat cycling routine in order to properly bed both pads and rotors.

- Conventional metallic shoes typically demand a more gradual break-in period which allows time for the friction materials to effectively conform with the surface of the rotors.

By adhering strictly to these recommended methods tailored for your specific type of brake system, you can guarantee peak performance, reliable functionality, and extended durability.

Each variant of brake pad—ceramics included—has its own distinctive set-up or preparation steps known as ‘bedding’, which are key for unlocking superior stopping capabilities inherent in their design.

Special Considerations for High-Performance Brakes

Disc brakes designed for high-performance, including those with drilled and slotted brake rotors, necessitate a specific brake bedding procedure to match their rigorous demands. These brake systems are akin to the endurance athletes of the auto industry. They need a precise bed-in routine executed with care to circumvent issues like judder while ensuring exceptional braking performance.

In the intensely competitive world of motorsport, robust high-performance braking systems undergo an essential break-in process tailored for them to withstand extreme operating conditions. The procedures involved in bedding these powerful brakes go beyond mere formalities—they play a pivotal role in fine-tuning their effectiveness and boosting vehicle performance during aggressive driving situations.

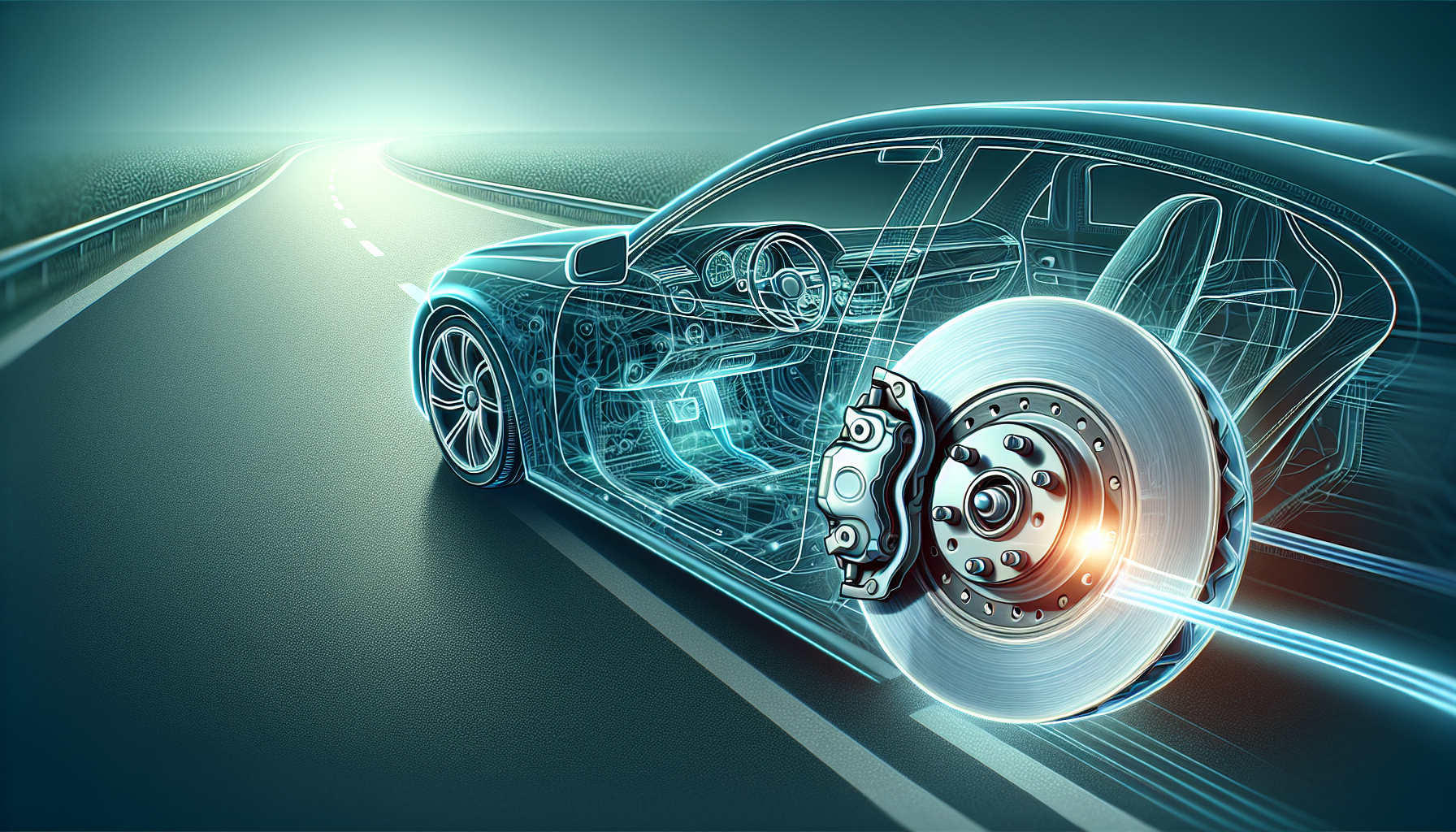

Everyday Cars vs. Racing Discs

Bedding in brakes for a regular passenger car is quite distinct from the brake bedding process used for racing machines. A typical family sedan requires several light decelerations from moderate speeds and then time to cool down, which transfers an even coat of friction material onto the brake rotors.

Conversely, race cars require a rigorous bed-in ritual often carried out on a racetrack. This entails cycles that begin with mild braking efforts escalating to high-intensity stops, succeeded by adequate time allowed for cooling off to properly adhere the pad material onto the discs. Such contrasting approaches highlight how different the expectations are for braking systems between standard vehicles and those designed specifically for motorsport performance.

Reading the Signs: Properly vs. Improperly Bedded Brakes

Understanding if your brakes have been adequately bedded is as essential as the brake bedding process. Recognizing the state of your brakes might be simple, such as observing a light blue hue and a gray film on the rotors. These signs indicate that they reached an optimal temperature and an appropriate amount of pad material has adhered to them. Assessing brake condition goes beyond simply noticing these visual indicators.

Success Indicators

The performance and sensation of your brakes significantly improve after a proper brake bedding procedure. When you apply pressure to the pedal, you’ll experience a smoother and more uniform response – these are indications that the bedding has been successfully completed. The lack of brake noise confirms that the pads and rotors are in excellent synchronization.

Such harmony between components results from an even distribution of pad material across the rotor surface, enhancing the overall smoothness during braking moments. This fine layer is crucial for achieving optimal interaction between pads and rotors, ensuring effective braking performance.

Red Flags to Watch For

Successful bedding of brakes is not guaranteed in every case. The brake bedding process is crucial, and warning signs like extended stopping distances are an alert to a potential decline in the performance of your car’s braking system, which could lead to safety hazards. These signs point towards insufficiently bedded brakes when increased room is required for the vehicle to stop completely and should not be dismissed as mere nuisances.

Visible indicators such as dark patches on rotor surfaces stand out as definitive proof of irregular pad material transfer – unmistakably signaling that the brake pads have not been adequately bedded into the rotors.

Do all brakes need to be broken in?

Not all brake systems strictly require a brake bedding procedure, yet the initiation of new brake pads and rotors significantly enhances their braking performance. Although some brakes may bed themselves through routine driving, it is often suggested that a deliberate break-in procedure be undertaken—especially for those frequently driving at high speeds or engaging in intense braking activities.

For newly installed brake components, the break-in procedure is vital to ensure they function at their best and last longer. Transferring an even layer of pad material onto the surface of the rotors prepares them for dependable and powerful stopping capability. Neglecting this step can result in inferior stopping power as well as unwanted pulsations through the brake pedal or vibrations felt within the steering wheel.

The establishment of adherent friction between pads and rotors—a key element for superior braking—is realized by correctly performing this bedding process. This technique creates a thin but uniform layer from the pad on to each rotor’s surface, essential for smooth and effective stops.

Summary

The brake bedding process for your vehicle’s brakes is essential for ensuring a reliable and efficient driving experience, which underscores the importance of not neglecting this phase. This process involves acclimating new brake components through an initiation that hinges on the correct application of heat and pressure to forge an optimal union between the rotors and pads. We have explored in depth both how vital it is to execute this bedding protocol properly and what could happen if ignored. We’ve discussed various methodologies tailored to bedding brakes, whether they’re intended for everyday use or engineered for high-performance demands, while also providing insights into identifying successfully bedded brake components.

Frequently Asked Questions

Why do new brakes need to be broken in?

New brakes need to be broken in to ensure even brake pad material transfer to the rotors, enhancing braking performance and preventing noise, while extending the lifespan of brake components.

Can I just drive normally to bed my brakes, or is a specific procedure necessary?

To guarantee optimal performance and extend the life of your braking system, it is advisable to adhere to a certain bedding protocol immediately after installing new brakes. This is particularly critical for those who often drive on highways or are prone to engage in intensive braking.

While your brakes may naturally bed-in over time with regular use, adhering to this suggested initial procedure plays a significant role in ensuring their peak performance from the outset.

What are the signs that my brakes have been properly bedded?

When brakes are correctly installed, they should operate quietly and with a uniform feel. They will display a slender, homogenous layer of the pad material on the rotor’s surface, characterized by a slight blue hue and gray coating on the rotors. Such discoloration signifies that an optimal temperature was reached for effective transfer of material from pad to rotor.

Do high-performance brakes require a different bedding process than standard brakes?

Indeed, brakes designed for high performance necessitate a specialized bedding process to endure demanding usage conditions. This involves conducting multiple heating and cooling cycles on a track to properly cure the brake pad material, ensuring optimal functionality of the pads during bedding and beyond.

What could happen if I don’t break in my brakes properly?

Failing to properly bed your vehicle’s brakes can result in several issues, including a pulsating brake pedal, extended distances required for stopping, and in severe cases, total brake failure—these problems significantly compromise the safety of your vehicle.

Properly bedding in your brakes is critical for maintaining comfort while driving and ensuring the overall safety of your vehicle.